|

Heinke (Siebe-Heinke)

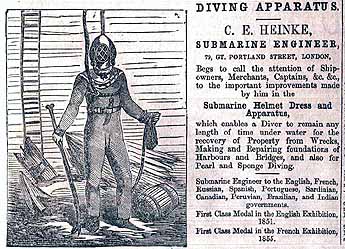

The roots of the Heinke company can be traced back to a man: Frederick Gotthilf Heinke (1786-1871). G.F. Heinke was an immigrant from Prussia and started his business in 1819. He had a workshop at 103 Great Portland Street (London). By 1858, the house numbering was changed to 79 Great Portland Street. For

business reasons, he applied for and obtained British citizenship in 1858. He had three sons and two daughters.

His second son, Charles Edwin Heinke (1818-1869), ran the family business and the firm was named "C.E. HEINKE" Submarine Engineers (1844-1871). Around 1844, Charles Heinke produced the first diving helmet and worked to improve the designs of the helmets of Augustus Siebe, who produced the first diving helmet in 1839.

With the death of Charles (1869), his brother William (1870) and his father Frederick (1871), Gotthilf Henry Heinke (1820-1899) continued the family business under the name "CE HEINKE & Co. " Submarine Engineers (1871-1922).

Henry brought a new associate to the company, William Robert Foster (from "Foster and Williams", that provided wetsuits and air pumps). In 1884, Henry Heinke retired and sold the company to Robert Fox (his brother-in-law) and William Foster. In 1899 William Foster died, and his company's shares were bought by three new partners: FH Sprang (who had shares in "Foster and Williams"), JH Blake and J. Holman.

The company "Foster and Williams" was incorporated by CE Heinke & Co. In 1922, Heinke became a public company and the company was renamed C.E. Heinke & Co. Ltd Submarine Engineers (1922-1961).

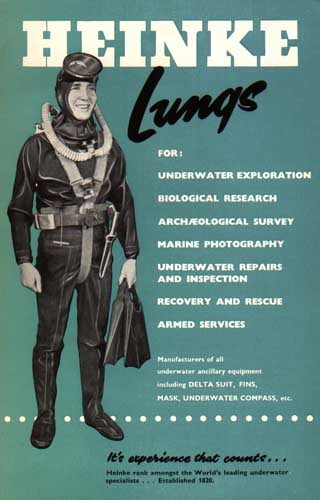

The new company was successful until the early 1950s, but, like so many companies, it stagnated in the post-war period due to a lack of innovation and investment.

In 1961, the EC. Heinke & Co. Ltd. was incorporated by Siebe Gorman & Co. Ltd.. During few years (1961-1967), some products were sold under a combined name "Siebe-Heinke". However, around 1968 this combined name was dropped with a return to the manufacturer's name "Siebe Gorman". Unfortunately, most of the Heinke company records were lost in the bombings during World War II. What was left of the Heinke company files were systematically destroyed by the company's former directors.

The project for the production of double hose regulators by Heinke began around the mid-1940s.

Heinke also wanted a part of the expanding sports market, but as Seibe Gorman

has obtained Spirotechnique's license to produce the CG45, they had trouble approving their project.

Heinke and Siebe Gorman were also great rivals in the production of diving equipment. In the early 1950s Siebe Gorman had obtained Spirotechnique's license over Aqua-Lung's Cousteau and Gagnan patent and produced the Siebe Gorman MK-I and MK-II regulators, and then the Mistral.

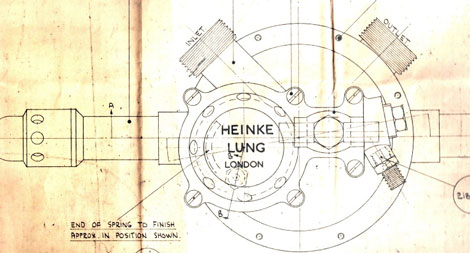

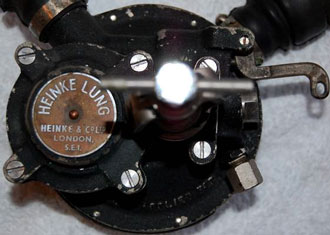

HEINKE DOUBLE HOSE REGULATOR (TWIN HORN) MK-I

The Cousteau-Gagnan patents, predominantly, protected the relative position of the exhaust valve near the diaphragm. With this license under his control, Siebe Gorman would not allow his rival to exploit this specific configuration. To conquer the new demand of the market for regulators, Heinke needed a different configuration.

It was already demonstrated that if the exhaust valve was positioned too far from the diaphragm, the regulator would go into freeflow, depeding from the position the diver was in, which would not occur with the exhaust valve at the same level as the diaphragm.

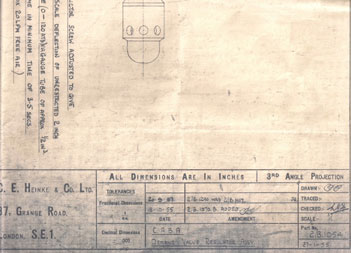

So, the company Heinke has come up with an ingenious solution to the problem. Using two diametrically opposed exhaust valves.

A pair of horns extended on each side of the regulator body, with a 6"/15 cm radius and with an exhaust valve mounted at the end of each horn. Therefore, they were able to escape the restrictions of the Cousteau/Gagnan patent.

With this drawing, while the horns were in the horizontal position, it did not matter what position the diver was in. Air could escape from both sides of the exhaust valves.

Thus, the twin-horn configuration from Heinke Lung MK-I. Heinke's first two-stage double hose regulator, emerged. The cast bronze construction of the regulator weighed 2.66kg. When mounted with rubber hoses covered, the weight increased to 3.16kg.

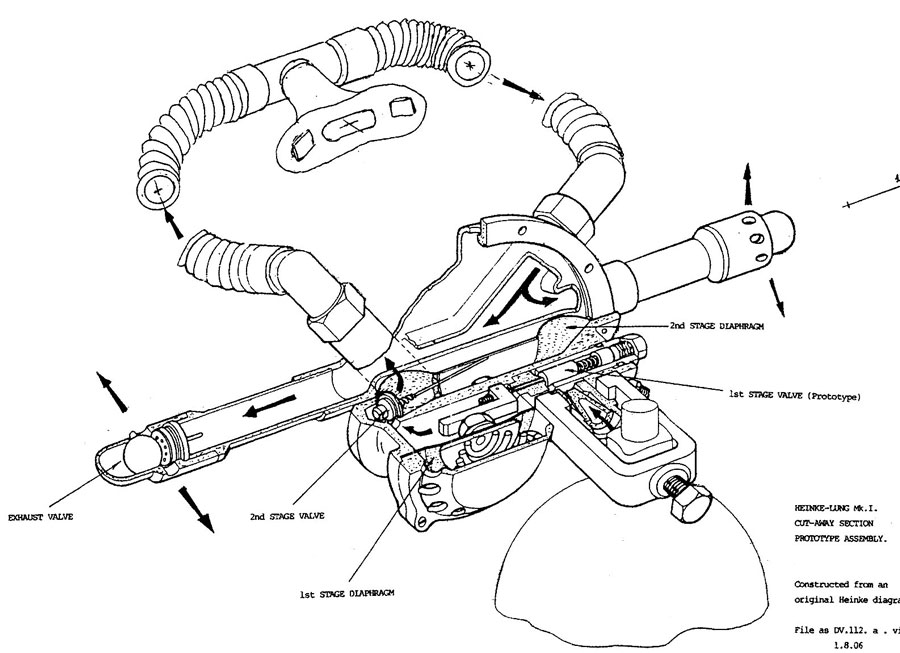

HEINKE DOUBLE HOSE REGULATOR (TWIN HORN)

MK-II

The Heinke Lung MK-II was the "de luxe" version of the Heinke Lung MK-I. It featured the same MK-I configuration, but with the addition of a by-pass valve that allowed the diver to "squirt" air directly from the high pressure inlet to the second stage chamber without passing through the first stage valve. This would allow

to remove the water from hoses and nozzle (remembering that there were no non-return valves on these models yet).

Also, it could be used to improve airflow temporarily, if the diver was in a very stressful condition and needing more air supply.

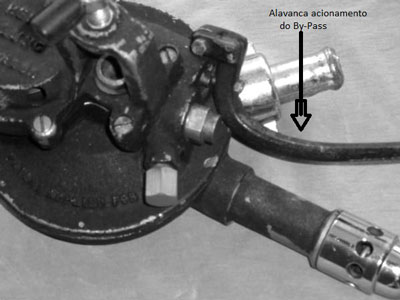

Picture 1

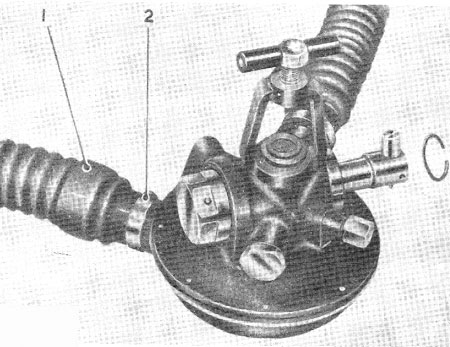

The by-pass valve was a piston type device placed parallel to the first stage valve and sealed by a small reinforced rubber diaphragm. It was activated by a large curved lever, resembling a bicycle hand brake, which in turn was connected to a traction cable placed on the diver's right shoulder. With a pull, a large amount of air was supplied directly from the high pressure side of the first stage to the second stage, passing (by-pass) the first stage valve completely.

HEINKE DOUBLE HOSE REGULATOR (TWIN HORN)

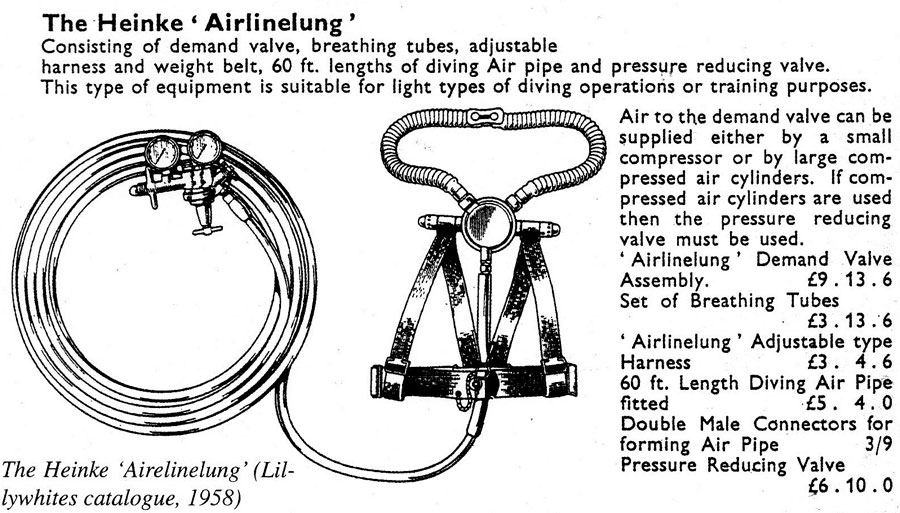

AIRLINELUNG

The third version of the Heinke Lung design was produced and was known as the "AIRLINELUNG" exclusively for use with air source coming from the surface (Narguilé). The surface model was intended for use in ports or civil engineering works.

The double hose regulators "Twin-Horn" was produced throughout the 1950s until they were replaced by the two-stage regulators Heinke Lung Venturi Jet MK-III and MK-IV.

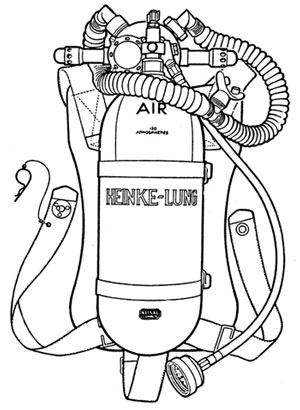

HEINKE DOUBLE HOSE REGULATOR VENTURI

JET MK-III

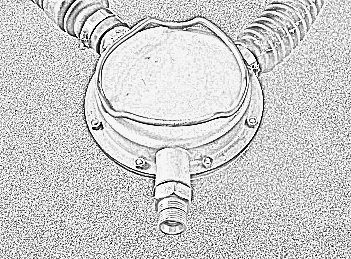

The MK-III Venturi Jet is produced with several modifications. The external shift that occurred from the original Heinke-Lung was the elimination of exhaust horns, which were replaced by a molded rubber cover with a single exhaust valve. The weight reduction was 900g. On the front of the regulator was placed the expression "VENTURI JET".

This change to a single exhaust valve, and the placement of the duckbill valve inside the new cover of the new regulator model, has bothered rival Siebe Gorman, who has alleged patent infringement. As the Cousteau-Gagnan patent had been written in terms of the location of the exhaust valve in relation to the diaphragm, but it did not define this in terms of the position in relation to the outlet of the exhaust valve. So, leaving the duckbill into the lid, Heinke moved it to the end of the exhaust valve, next to the exhaust hose. This left the modification performed outside the dimensions and constraints of Cousteau-Gagnan's patent.

The main improvement of the MK-III project was the addition of Venturi Jet in the second stage, which gave its name to the regulator. A metal tube that directed the airflow from the inhalation valve to the inlet hose, causing the desired venturi action. Rubber non-return valves have been placed in rigid compartments inside the mouthpiece on both sides. The old bolted couplings of the hoses were also eliminated, which were replaced by thin metal clamps.

Picture 2

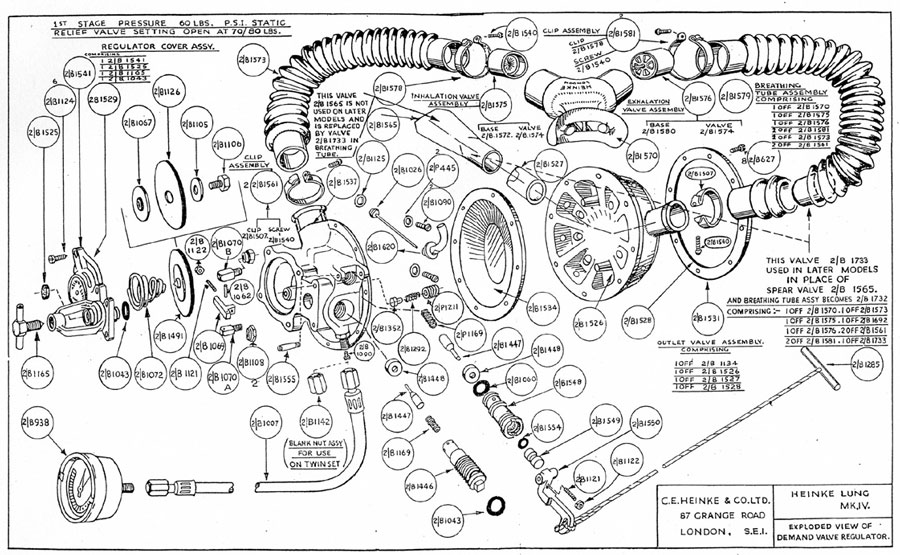

HEINKE DOUBLE HOSE VENTURI JET MK-IV

The double hose Mk-IV Venturi Jet regulator was created by adding a by-pass valve (in the first stage) in the MK-III Venturi Jet design, which resembled all other details. Both regulators were manufactured in the same period. The drive lever was now much shorter with a 1 ¼ "machined crank, with the drive cable running over the diver's right shoulder. With the non-return valves in the moutpiece included, the function to remove water from hoses, which existed on the MK-II, lost some sense, but the function of allowing a quick supply of air to the diver when necessary was still advantageous.

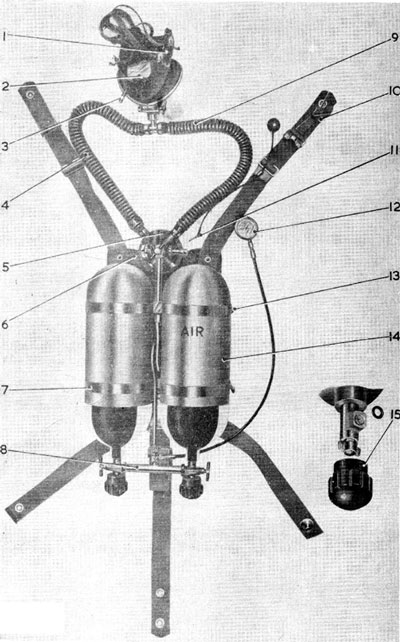

HEINKE DOUBLE HOSE VENTURI JET

AIRLINELUNG

As with the Twin-Horns, there was also a Heinke Venturi Jet Airlinelung version, which was exclusively used a surface air source. Three stirrups were attached to the back of the metal enclosure, which allowed the regulator to stick to the harness. The inhalation and exhalation hoses were on the diver's shoulders and the air inlet tube was at the bottom of the regulator, so the hoses formed the letter "Y". The expression on the front of the regulator was HEINKE LONDON - AIRLINELUNG VENTURI JET.

But there was no Venturi Jet effect in this regulator model because, of the positioning of its inhalation and exhalation valves, there was no space for venturi placement.

During this period, some Twin-Horns were changed during maintenance by removing their dual exhaust system and replacing it with the new rubber cover. They were known as Hybrid Venturi Jets.

The MK-III and MK-IV Venturi Jet double hose regulators were produced throughout the late 1950s.

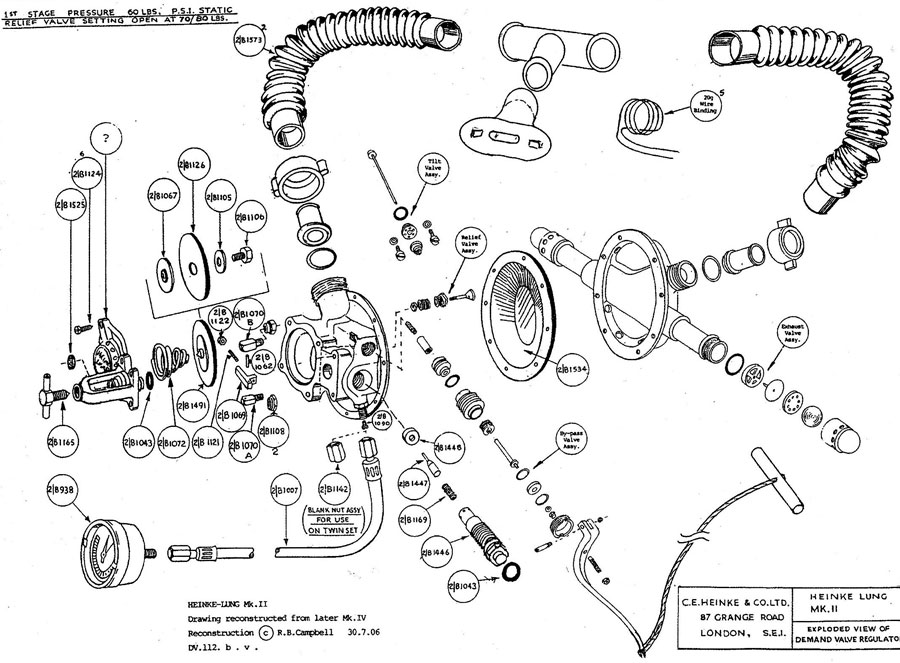

HEINKE DOUBLE HOSE REGULATOR

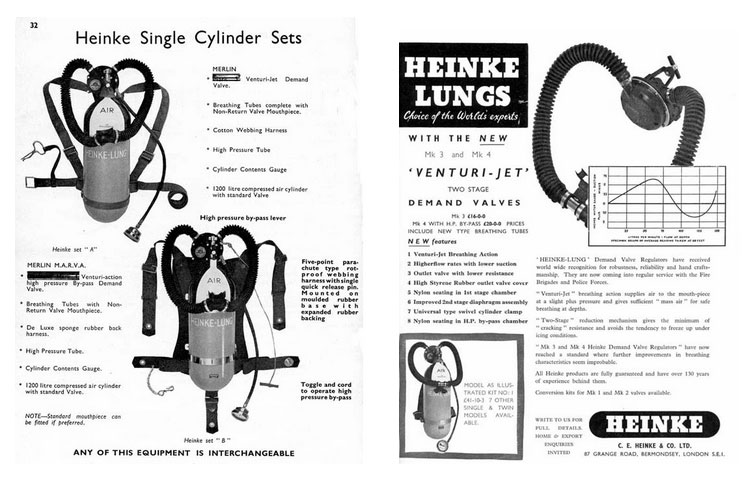

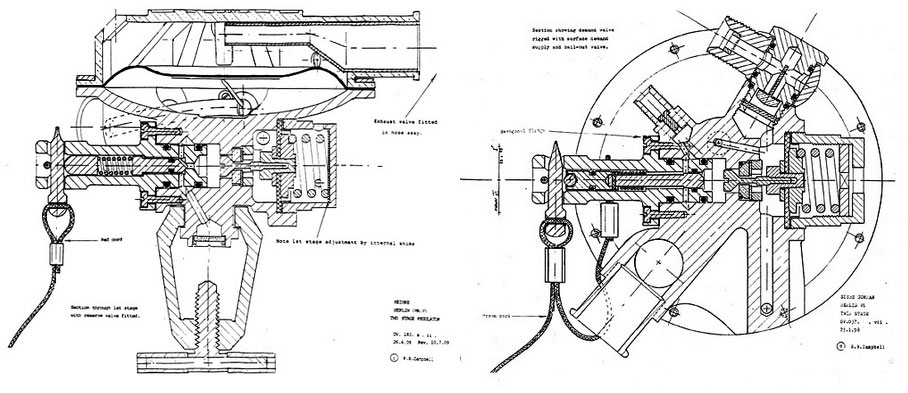

MERLIN

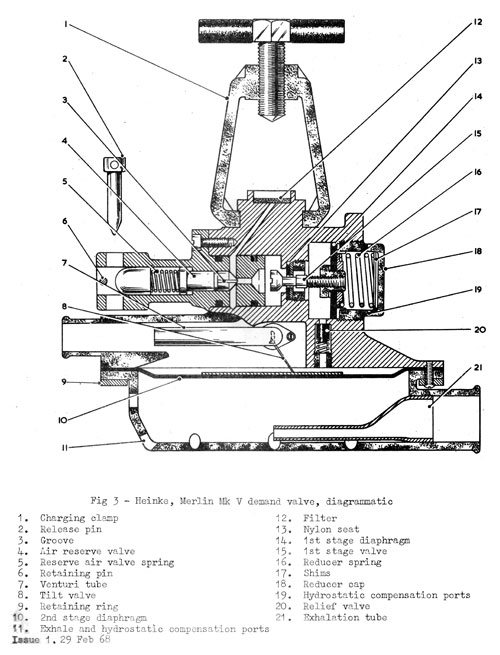

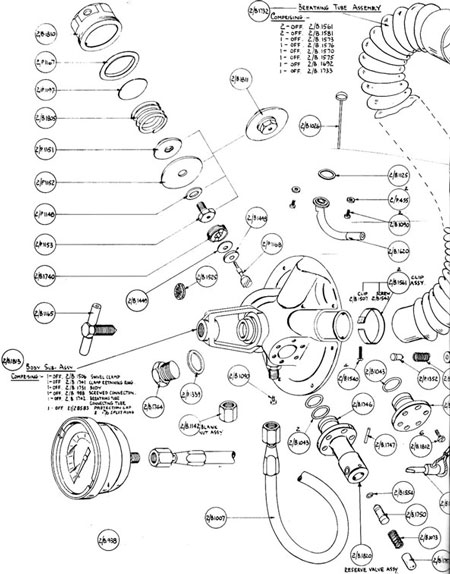

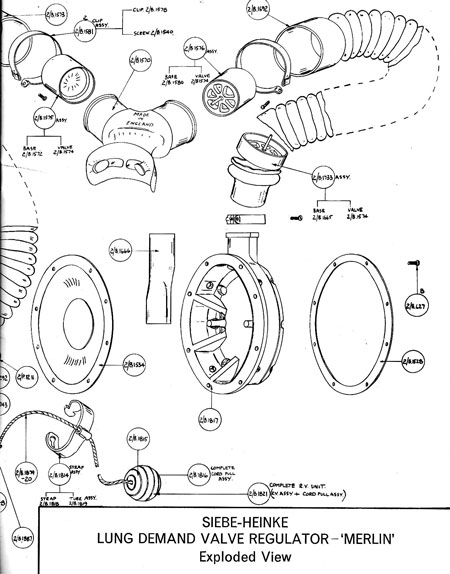

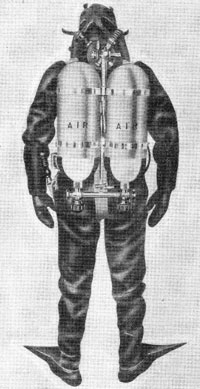

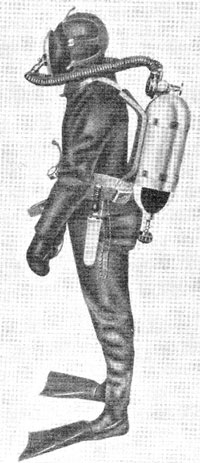

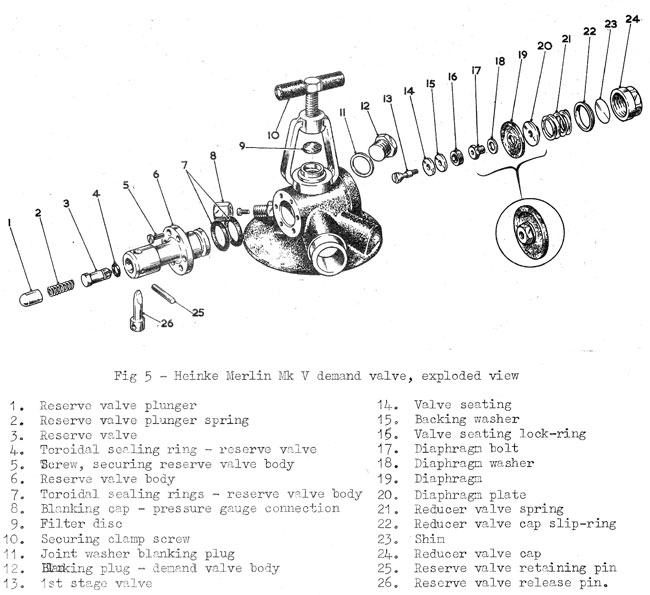

The Heinke Merlin was introduced at the end of 1961. In their designs they appeared under the name Heinkelung MkV DVR, but in the ads for sale it appeared described as MERLIN with MARVA (Mechanical Air Reserve-Airlinelung). A two-stage regulator that inherited some characteristics of the Venturi Jet MK-III and MK-IV:

- Set of hoses with non-return valves in the nozzle;

- Built-in exhaust valve;

- Venturi Jet system;

- Internal relief valve;

- Top cover of molded rubber regulator, which now featured the expression MERLIN HEINKE - London - Made in England;

Pictures 3 e 4

Although the second stage was the same as the Venturi Jet, the first stage was redesigned. It had, as an option, a reserve valve that could be driven through a rope that came over the diver's right shoulder when the airflow decreased with the cylinder pressure drop. An air-fed version of the surface was also made for Heinke Merlin. The regulator would then work with the surface air source and use the cylinders as a backup source.

This model presented some flaws. The addition of a Bail-Out valve, which was placed next to the reserve valve, was also driven by a rope that released air from the cylinder. The appearance of the Bail-Out valve and reserve valve was similar. A flange with hexagonal details and a green rope for the Bail-Out valve was used, as opposed to the red color for the reserve valve rope.

SIEBE-HEINKE DOUBLE HOSE REGULATOR MERLIN

The production of Heinke Merlin began in 1961. But shortly thereafter, between 1961 and 1962, the company was acquired by its great rival to Siebe Gorman. Merlin continued to be produced by new owners.

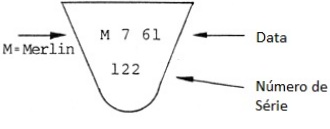

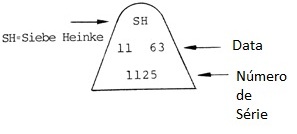

The Heinke-Merlin can be identified by its serial number, date of manufacture and initials that are stamped on the triangular part of the regulator body.

When Siebe Gorman took over, they created the name Siebe-Heinke for the commercialization of diving equipment. And they put the number next to the name of the regulator: MERLIN MK-V. The regulator construction pattern remained unchanged. In fact, the molded rubber components of the top cover and the nozzle still carried Heinke's original markings.

The manufacturer's change can be identified by the serial number, which now appears in the form of the initials SH, which continued to be used even in the Siebe Gorman Merlin MK-VI regulators. SH initials and date can be stamped on a single line.

In 1963, the name Siebe-Heinke appeared for the last time in the catalogs.

SIEBE GORMAN DOUBLE HOSE REGULATOR MERLIN MK-V

Subsequently, Siebe Gorman has altered the molds to eliminate the Heinke embossed name. This produced a flat part at the top of the regulator where an adhesive label would be glued saying that the regulator was a Siebe Gorman Merlin MK-V. The nozzle was also changed to include the name Siebe Gorman, plus an arrow indicating the direction of the airflow. Most regulators with this label have worn out over time, but it is still possible to find some regulator labeled Siebe Gorman Merlin MK-V intact.

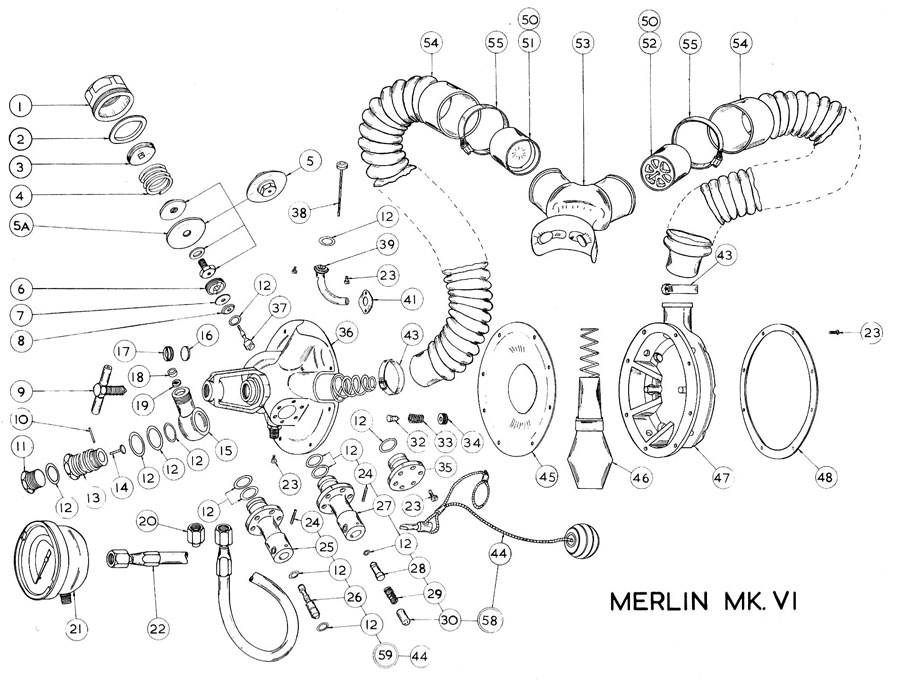

SIEBE GORMAN DOUBLE HOSE REGULATOR MERLIN

MK-VI

Some improvements were made by Siebe Gorman to produce the MK VI. The top cover of the regulator was lowered so that the label "Merlin Mk VI" was placed. This recess protected the wear label from abrasion. A new project for a new placement of the "duck-bill" was made. Modifications in the first stage seat for better sealing for use with higher pressure cylinders, as well as some improvements in the second stage. The venturi was shortened to improve its position with respect to the outlet to the inhalation port.

Reference:

1. http://www.divingheritage.com/siebekern.htm

2. John Salsbury;

3. Historical Diving Times Magazine #40

4. Historical Diving Times Magazine #43

5. Frank Werthwein

6. Historical Diving Times Magazine #48

7. Pictures 1, 2, 3 e 4: Copright de Bob Campbell - Publicados

com sua autorização

|