|

Loosco

Loos & Co was founded in 1890 by Goossen Leendert Loos. He

started a one-man business in an old house in Amsterdam. With his

saved money he began distributing and importing gas for mineral

water. This mineral water is still being sold today as Victoria

water. In 1910 he expanded his company by trading in oxygen and in

1918 he started manufacturing oxygen to supply the Dutch market.

In 1938 the company changed its name to G.L. Loos & Co's

Fabrieken N.V. using Loosco as a trademark.

Before and after the Second World War the Dutch engineer Jan

van Buuren developed many important pressure regulators for

welding for both surface and underwater use, and also medical

anesthesia equipment. G.L. Loos & Co. asked him to design

breathing equipment for underwater use. After World War II many

people and lots of gear were needed to clean up all the harbors in

Holland. Loosco advanced to become the largest supplier of

equipment for this challenge. Together with his teacher, Gilrath,

who was a German engineer and employee of Loos & Co, Jan van

Buuren developed the first twin-stage double hose regulator for

the Dutch market: "The Egg."

Jan van Buuren

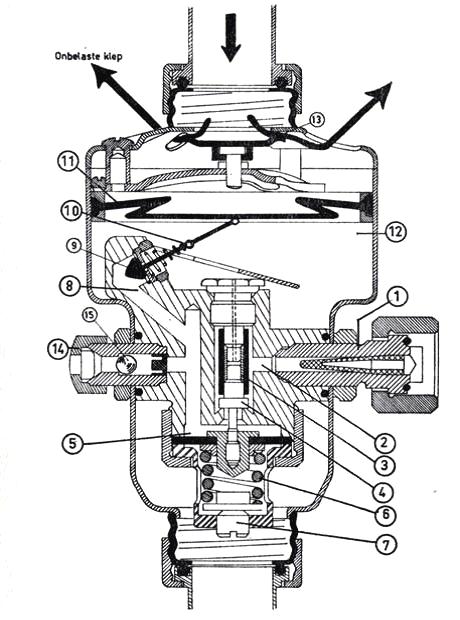

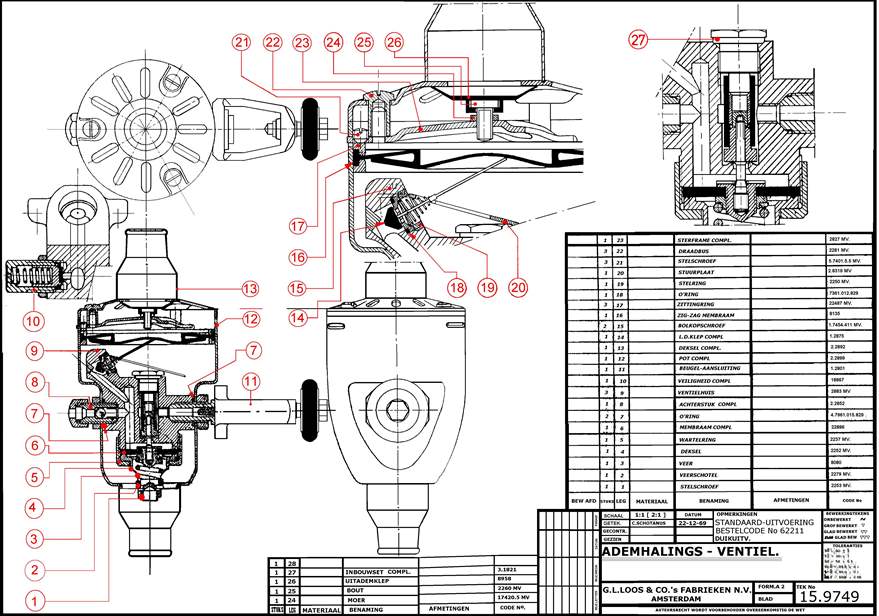

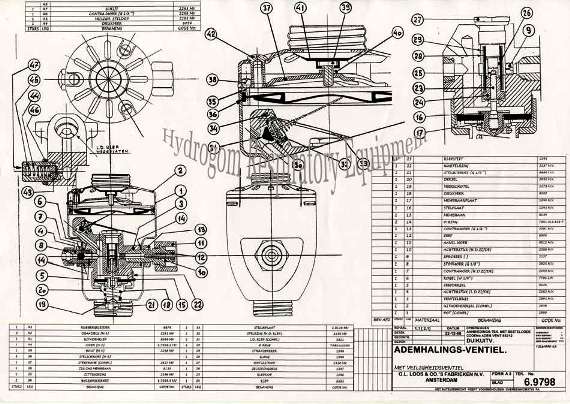

The unusual design of The Egg based on early principles of a

balanced high pressure seat.

The Cousteau-Gagnan regulators were constructed as single stage

regulators at that time, not having a balanced high pressure seat

system.

Jan van Buuren and Gilrath were ahead of their time with this

construction. In the years 1955/56, Jan van Buuren created the innovative compensated regulator valve,

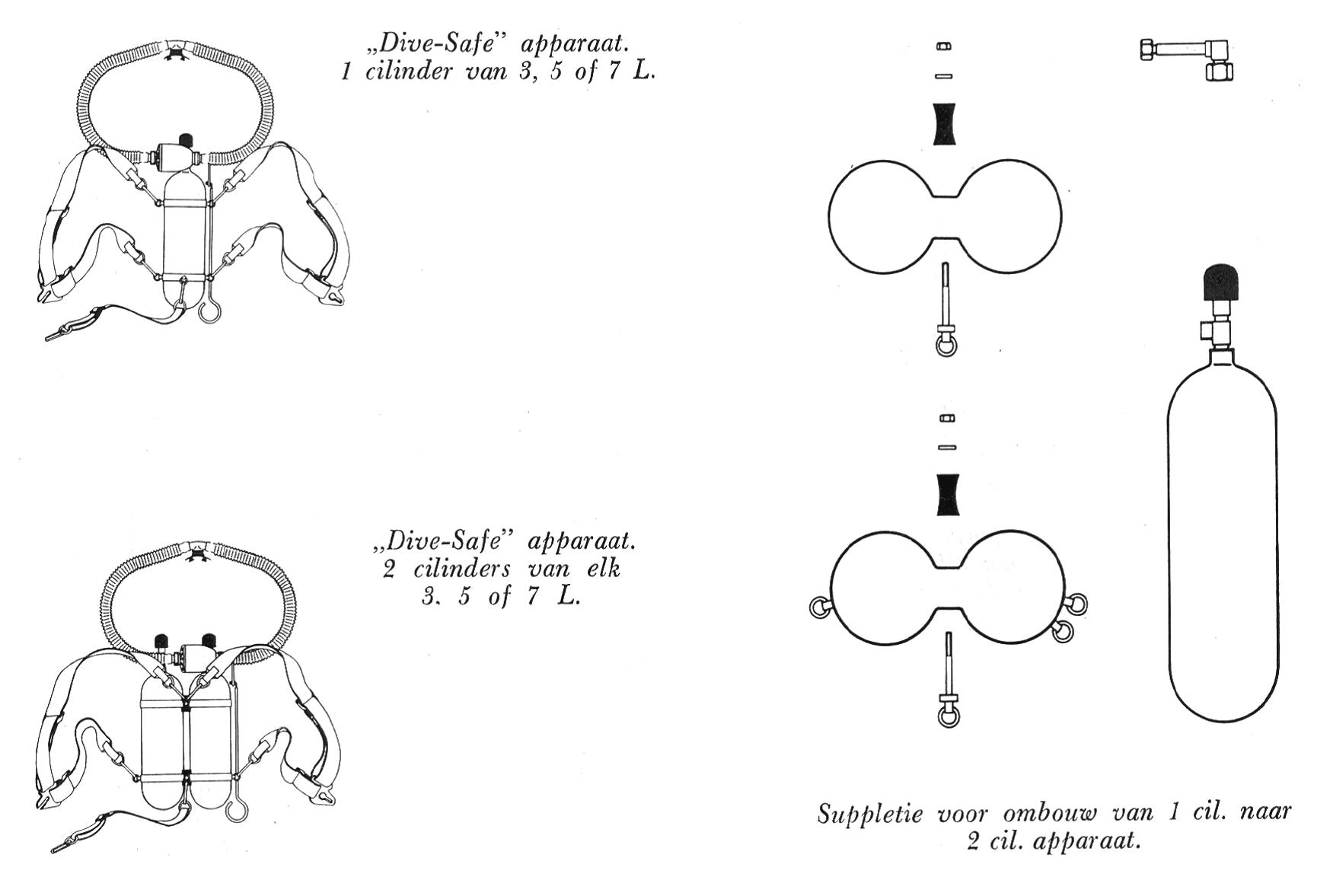

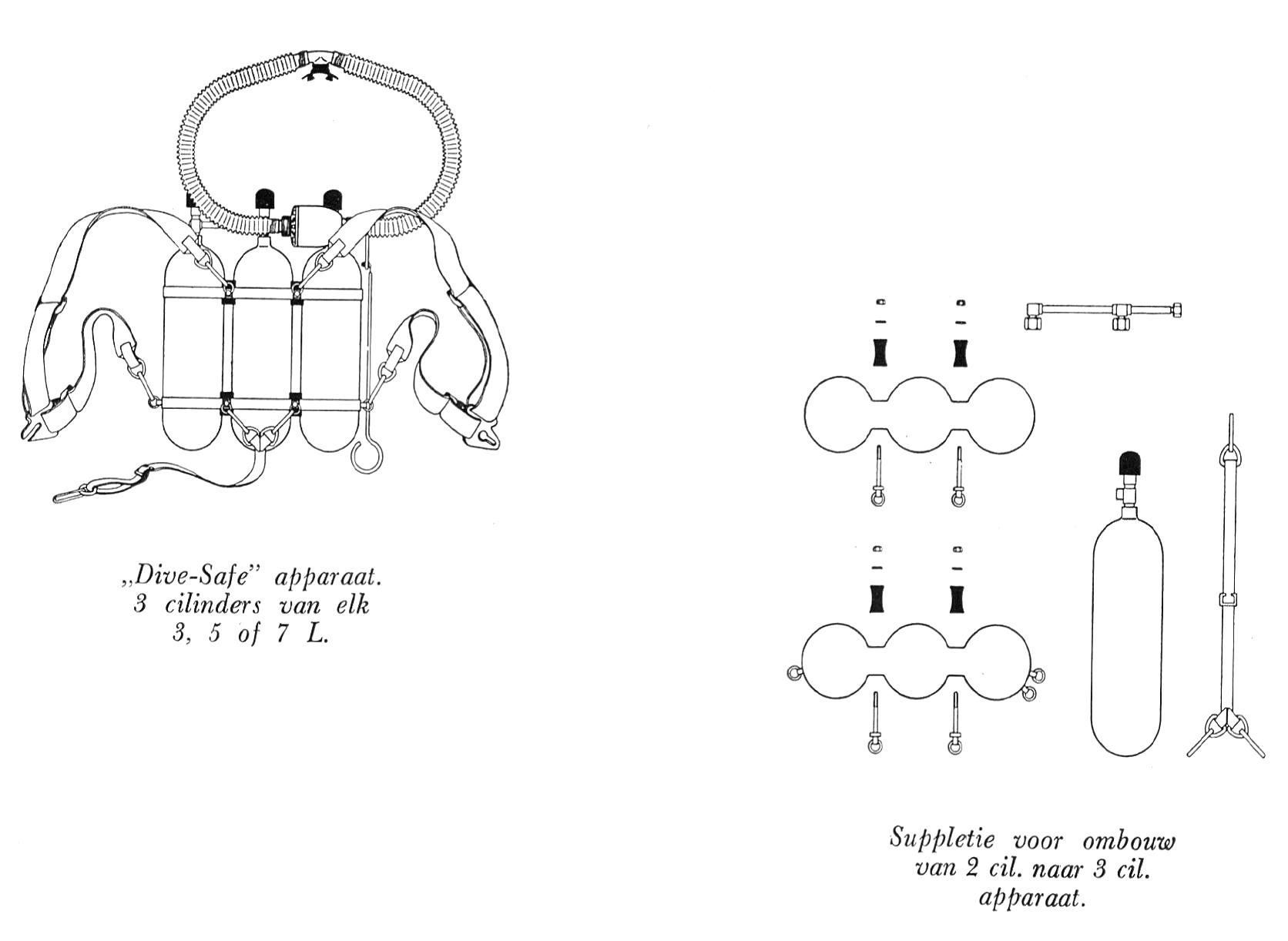

that was the basis for the whole "DIVE SAFE DIVER EQUIPMENT "of the company

Loos & Co.

The first regulators nicknamed "Loosco egg", came on the market

in August 1957.

The Loosco Egg was tested up to 150 meters depth by French Navy and surprised everyone. The "non-pressurized" valve worked

outstanding.

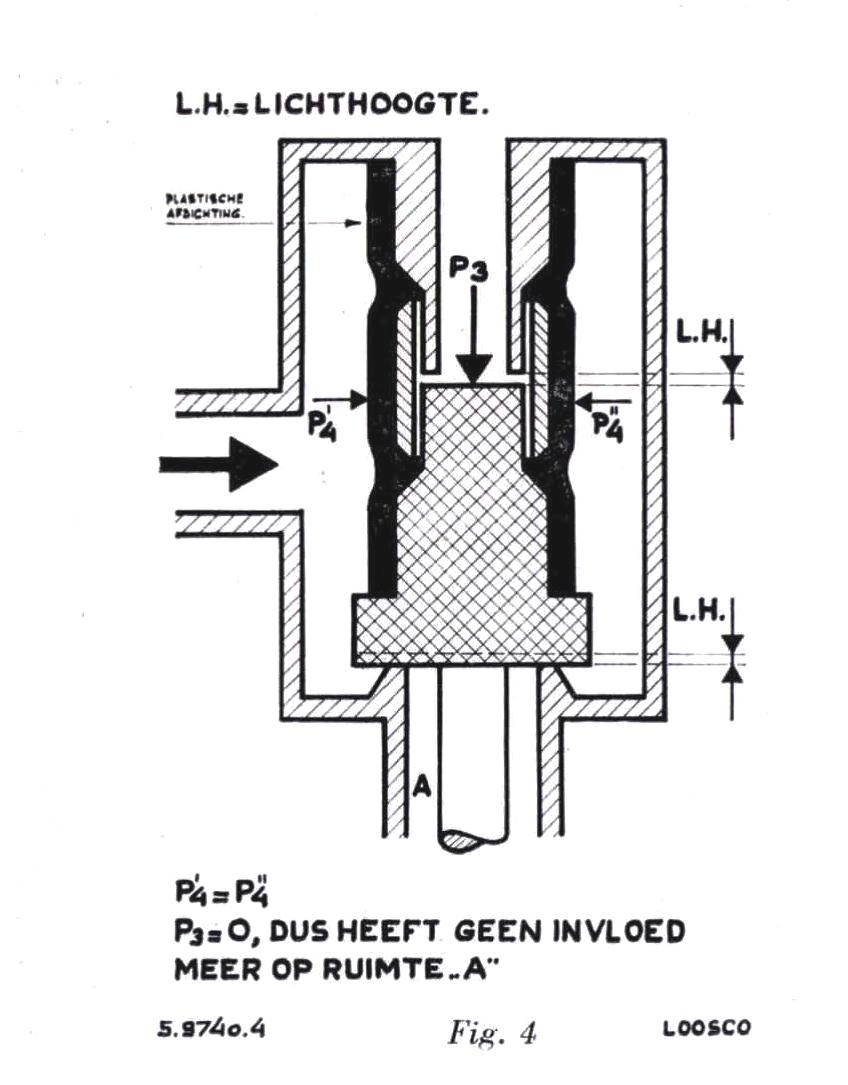

The first stage of this regulator is based on a number of innovative ideas that today are not reflected in the modern compensated

single hose regulators. Neither in the first compensated two hose

regulator of Gagnan, the Royal Master (1963).

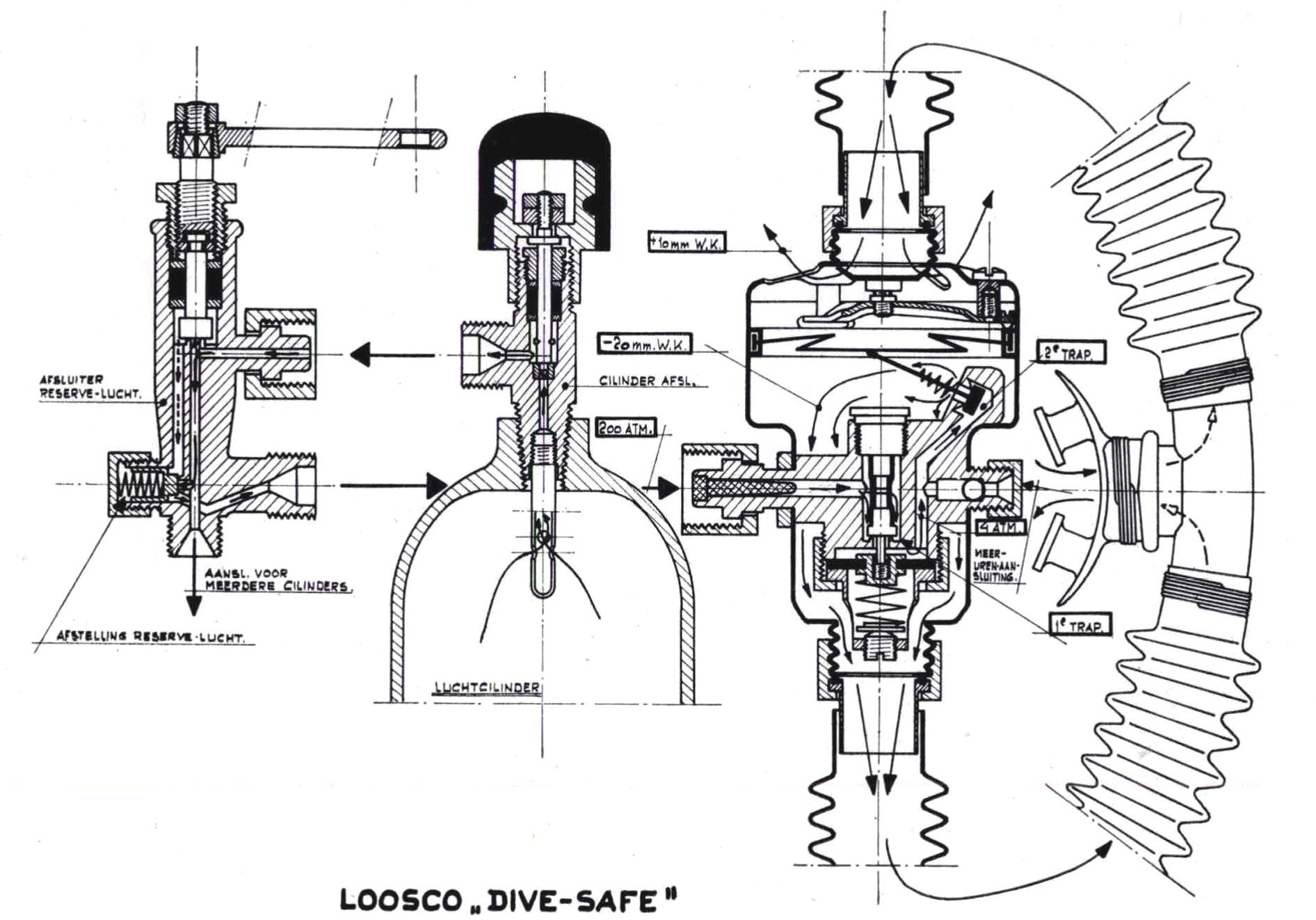

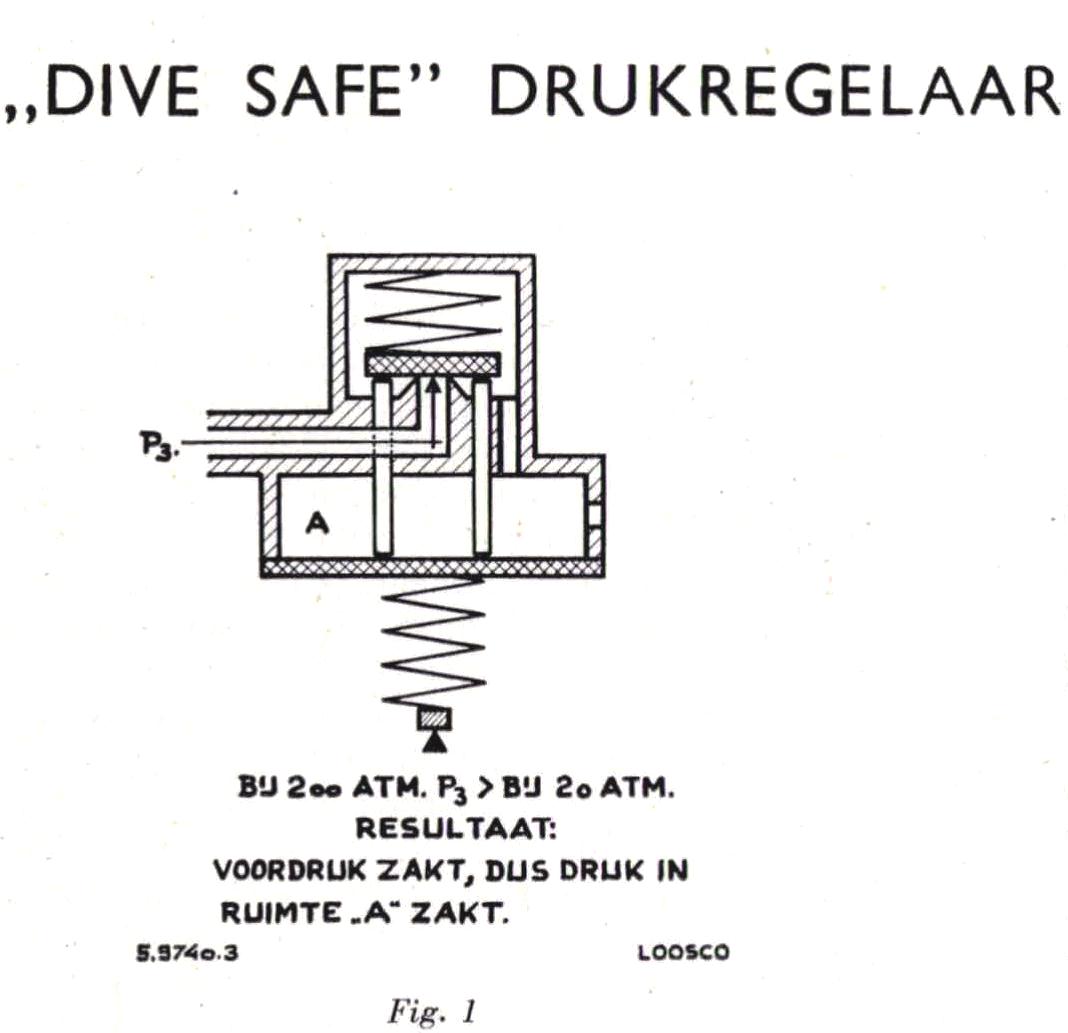

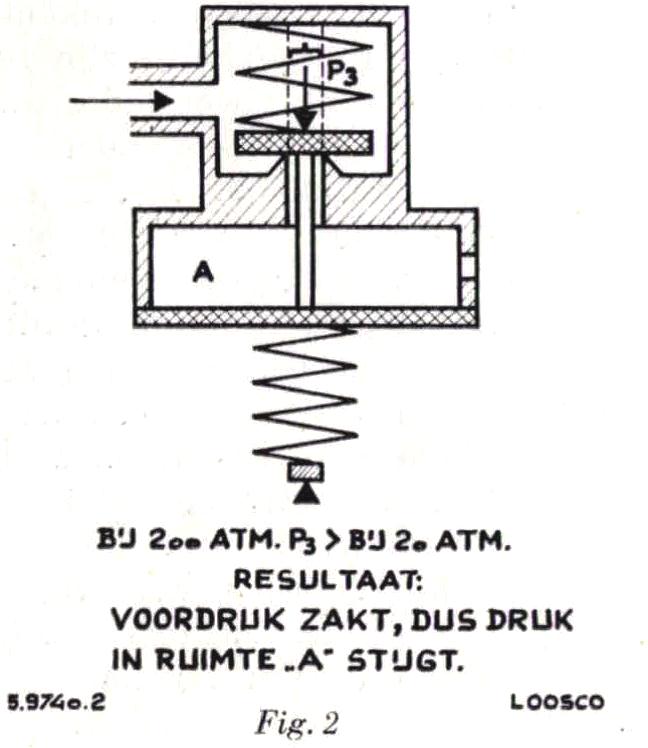

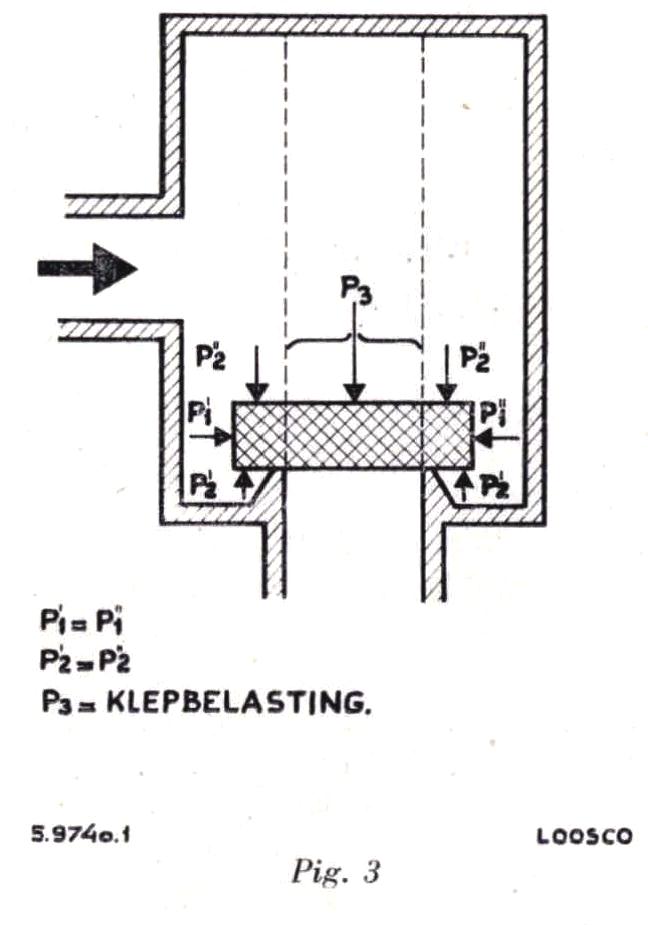

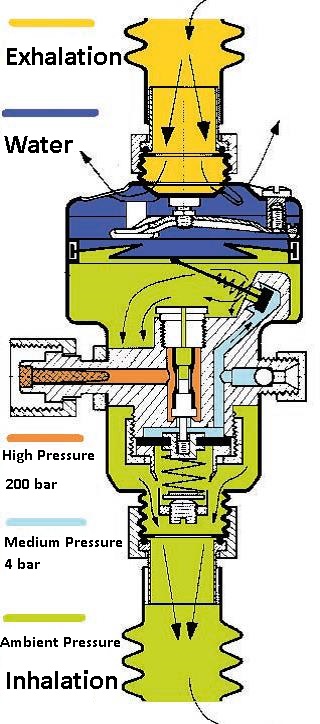

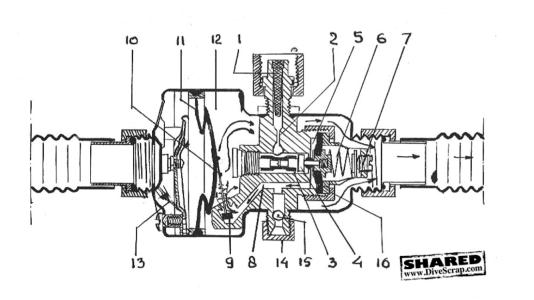

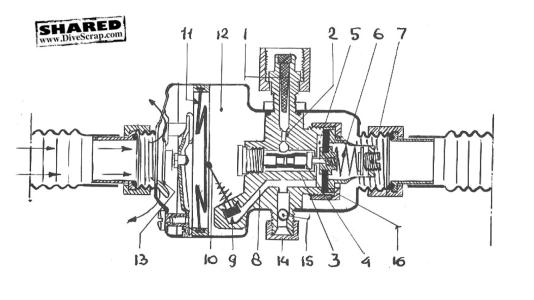

On the high pressure piston, the pressure in the diaphragm chamber acting through the diaphragm of the

ambient pressure depends, not the medium pressure, as in the Royal Master and today's

regulators. The entire two control stages can remain dry, as the water pressure acts only indirectly through the main membrane (see scheme of the controller), which is important for the icing security.

The unusual form of the Loosco egg, which is only found once again with the Viking regulator from the USA, which came on the market in 1955, results from this principle.

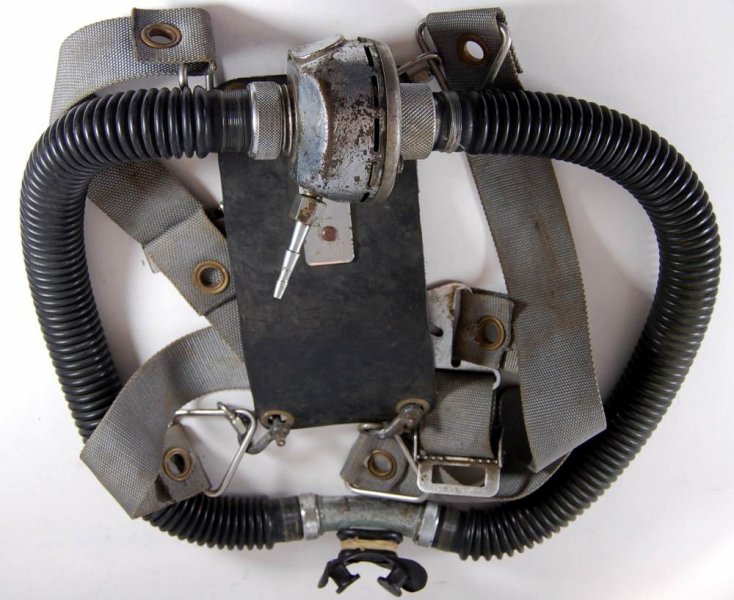

There were three slightly different versions of the regulator on the market. V1 is the original form for professional diving with roller thread connections for the hose sockets.

At V2 version, rings were used for direct attachment of the straps provided on the regulator for the scuba diving equipment. Loos & Co made these two designs with a folded tubing with a curved mouthpiece, but with an inappropriate bite piece and rejected by many divers.

That's why later you could buy tubes and mouthpieces from La Spirotechnique and use

them in the Loosco egg.

In V3 version the hoses were plugged directly in the regulator, without screw caps.

The Loosco "egg" regulator was produced from 1957 to about

1975. Unfortunately nothing is known about the production volume. However, he was in use among Dutch military, professional and recreational divers in relatively large numbers and this until the

1980s. The company continued to produce diving equipment in its large range of medical and diving equipment.

In 1961 Loos & Co lost the international competition with La Spirotechnique. Van Buuren was dismissed and replaced by two engineers who also developed other diving equipment for the domestic market. After a year, Jan and his son Bas set up a mold making factory for casting and injection molding products. Here he developed the single-hose regulator Divemaster, of which over 150 units were built in house. This is a regulator with a compensated high pressure stage and a snorkel on the mouthpiece, which can be switched with a rotary knob, a principle that has not prevailed in the long term.

Based on his wealth of experience, Jan van Buuren returned to Loos & Co after seven years, where he worked until his retirement. Often customers came with regulators, which had to be repaired.

The compensated regulator valve from Jan van Buuren is still used today because of its freedom from maintenance in the medical industry.

Unfortunately, his idea has never been patented.

There is a small version of the Loosco

"egg" that is a surface and shallow water double hose regulator

to fits on a fullface mask. It is for using in shallow water until

about 5m. The air comes directly of an air upply with a pressure

around 4.5bar. There is a large amount of hose to do work in pipeline's,

ships and other irrespirable atmonsphere's places. It was a cheap

product and after the jobs this equipment this equipment was thrown away.

Because of that it is not easy to find one in good conditions.

Pictures: Jeroen

Gompelman

CG-45 Colection

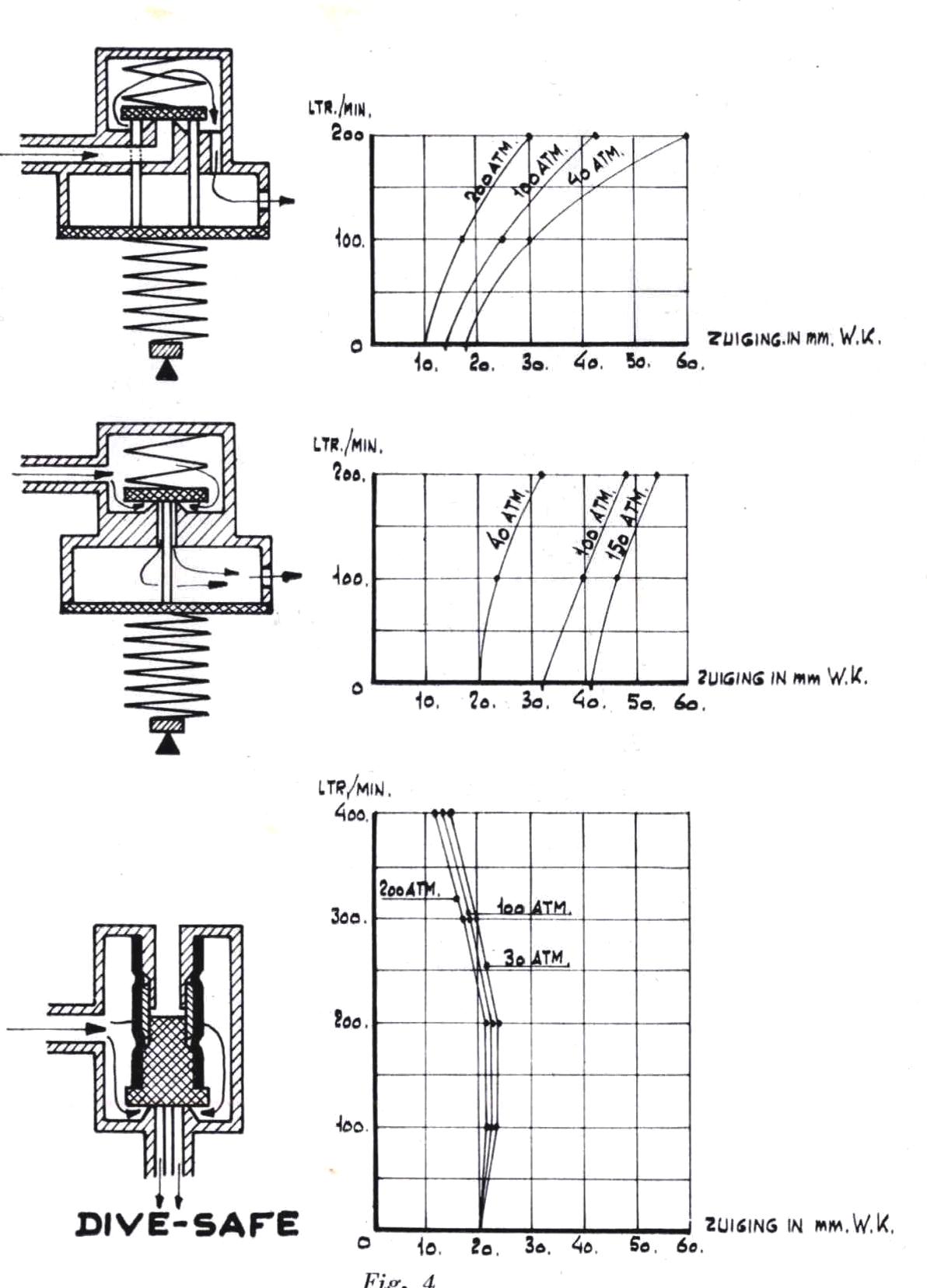

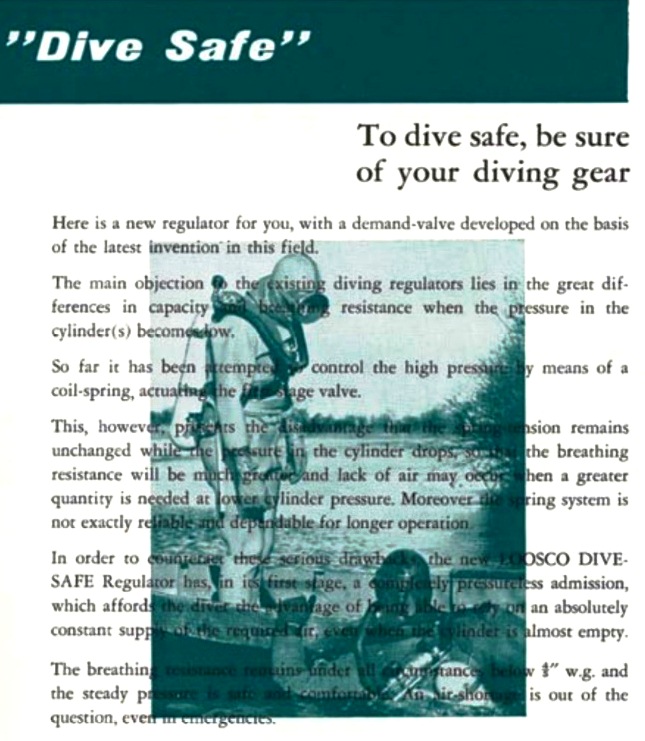

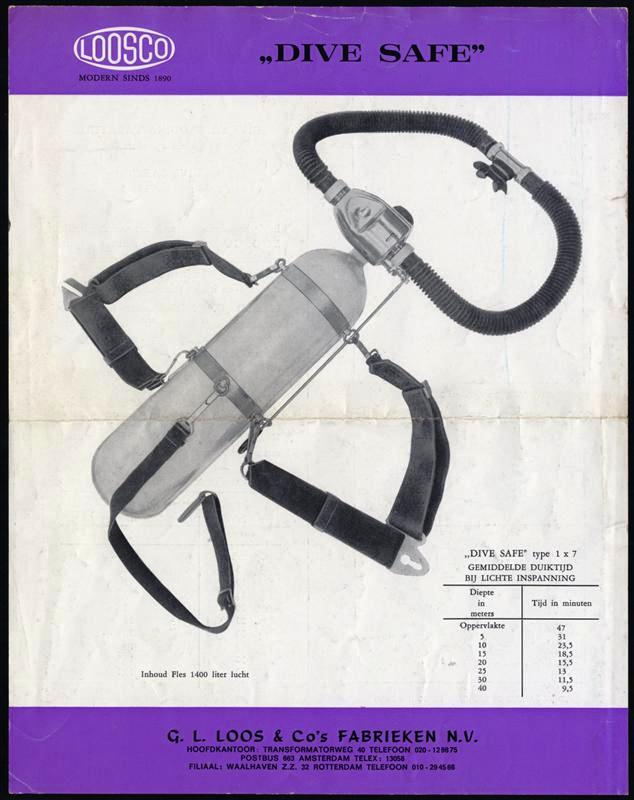

In the LOOSCO DIVE SAFE CATALOG you could read:

"The main objection to the existing diving regulators lies is the great differences in capacity and breathing resistance when the pressure in the cylinder(s) becomes low.

So far it had been attemped for control the high pressure by means of a coil spring actuating the first stage valve.

This, however, presents the disvantage that the spring tension remains unchanged while the pressure in the cylinder drops, so that the breathing resistence will be much greater and lack of air may occur when a greater quantity is needed at lower cylinder pressure.

Moreover the spring system is not exactly reliable and dependable for long operation.

In order to contered these serious drawbacks the LOOSCO DIVE SAVE regulator has in its firts stage a completely pressureless admission, wich affords the divers the advantage of bring able to rely on an absolutely constant suplly of the required air, even when the cylinder is almost empty.

The breathing resistance remains under all circunstances bellow 4/5" w.g. and the steady pressure is safe and confortable."

Reference:

1."European Vintage Scuba Event Lake Marx,

Germany" by Franz Rothbrust - The Journal of Diving History -

Fall 2010, Volume 18, Issue 4, Number 65.

2. Het

Ei van Jan van Buuren - by Jeroen Gompelman.

3. Loosco

Manual.

4.

Scuba Divers - Loosco Catalog.

5.

Jeroen Gompelman (Hydrogom Respiratory Equipment)

emails with information.

6.

David Decker - http://www.divescrap.com/DiveScrap_INDEX/Images_Loosco.html#0

|